Custom DC Connector Supplier

Professional OEM/ODM DC connector manufacturing with 20+ years expertise. Minimum order from 1000pcs • 15-30 days delivery • Full customization support

Your Trusted DC Connector Supplier

XiangOu Solar has been manufacturing premium DC connectors since 2005, serving global markets with ISO9001:2015 certified quality management. Our dedicated international team provides comprehensive pre-sales consultation and lifetime technical support.

20+ Years

Manufacturing Experience

ISO Certified

Quality Management System

50+ Countries

Global Market Presence

24/7 Support

Technical & After-sales

Explore Our DC Connector Series

Industry-leading photovoltaic connectors engineered for reliability, performance, and longevity in demanding solar applications

MC4 Solar Connectors

IP67 rated, 1000V/30A capacity. Ideal for residential and commercial solar installations. TUV certified with anti-UV materials.

MC4 Plus Connectors

Enhanced 1500V/40A design for high-power applications. Advanced locking mechanism with tool-free installation for utility-scale projects.

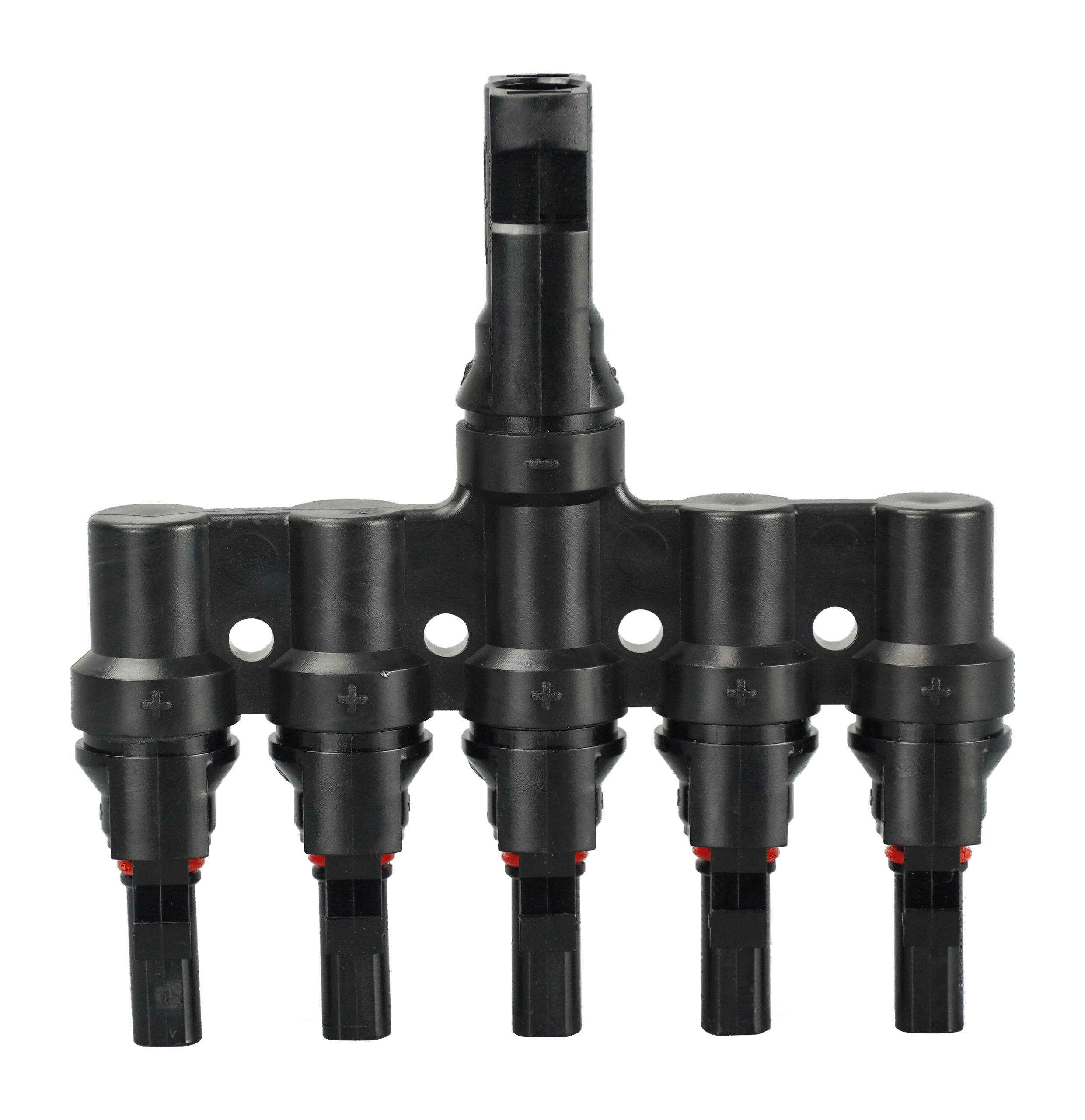

Branch Cable

High-performance solar branch cables with MC4 connectors. UV-resistant XLPE insulation, rated for 1500V DC systems. Essential for parallel string connections.

Custom DC Solutions

Bespoke connectors designed to your specifications. Custom voltage/current ratings, materials, colors, and packaging options available.

Ready to Power Your Solar Project?

Connect with our engineering team for custom solutions tailored to your specific requirements

Why Partner with XiangOu

Experience the difference of working with a premium DC connector manufacturer committed to excellence

Supply Chain Excellence

Streamlined production with 15-30 day standard delivery. Express options available for urgent orders. Strategic inventory management ensures consistent availability.

Cost-Effective Customization

Competitive pricing with volume discounts. No hidden fees for standard customizations. Transparent cost breakdown for all project components.

Quality Management

ISO9001:2015 certified processes. 100% factory testing with comprehensive QC reports. Third-party certification support available.

Technical Support

Direct engineer communication for design optimization. Free technical consultation and compatibility analysis. Comprehensive documentation provided.

Compliance & Certification

TUV, CE, RoHS, UL certifications available. Support for region-specific compliance requirements. Complete traceability documentation.

After-sales & Warranty

Standard 2-year warranty with extended options. Global technical support network. Rapid response for quality issues and claims.

Frequently Asked Questions

Get instant answers to common questions about our solar electrical components, manufacturing processes, and business terms.

Still have questions?

Our technical experts are ready to help you find the perfect solar electrical solution for your project.

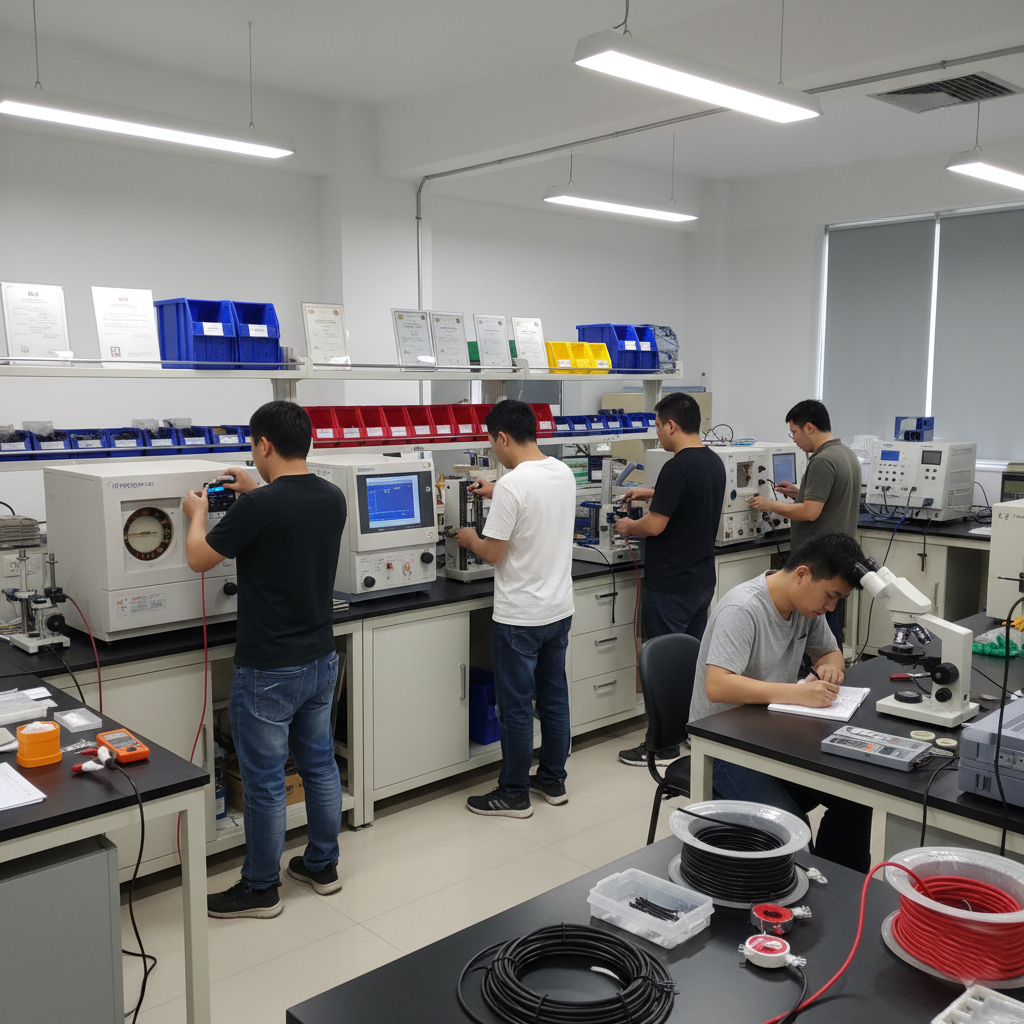

Production & Quality Control

State-of-the-art manufacturing facilities delivering premium solar electrical components with uncompromising quality standards

Manufacturing Excellence

Advanced Production Lines

4 automated production lines with capacity of 500,000+ connectors monthly. State-of-the-art injection molding and assembly equipment.

Clean Workshop Environment

5S methodology implementation with climate-controlled environment. ESD protection and contamination control protocols.

Comprehensive Quality Testing

Incoming material inspection, in-process monitoring, and final product testing. Automated testing equipment for electrical parameters.

Main Production Floor

Advanced manufacturing facility

Assembly Line

Testing Lab

Custom Packaging

Anti-static bags, custom boxes, palletizing, and branded packaging options

Certifications

ISO9001, ISO14001, TUV, CE, RoHS, UL certifications maintained

Testing Equipment

Automated electrical testing, thermal cycling, and mechanical stress testing

Traceability

Complete batch tracking and material traceability for quality assurance

Quality by Numbers

Two decades of manufacturing excellence delivering consistent quality

Monthly Capacity

Quality Rate

Years Experience

Certifications

The Ultimate DC Connector Guide

Comprehensive resource for engineers, procurement managers, and project managers. Solve selection challenges, optimize costs, ensure compliance, and minimize risks in your DC connector projects.

Guide Contents

Key Questions Answered

How do I quickly determine if a DC connector suits my application?

Evaluate voltage/current requirements, environmental conditions (IP rating), mating cycles, and installation constraints. Our compatibility matrix simplifies the selection process.

What are the 3 most critical parameters when choosing DC connectors?

1) Voltage/current rating with safety margin, 2) Environmental protection (IP rating), 3) Contact resistance and temperature rise under load conditions.

How do materials and manufacturing processes affect performance and cost?

Housing materials (PA66 vs PPO) impact temperature resistance. Contact plating (tin vs silver) affects conductivity and corrosion resistance. Manufacturing precision influences reliability and cost.

What's the most effective approach to custom connector development?

Start with detailed requirements specification, create 3D models for fit verification, prototype testing for electrical/mechanical validation, then scale to production with quality controls.

Start Your DC Connector Project Today

Get rapid response within 4 hours, customized solutions, free samples, and exclusive pricing for new partnerships. Our engineers are ready to optimize your connector requirements.

Our Capabilities

4-Hour Response

Rapid technical consultation and quote delivery

Custom Solutions

Tailored DC electrical components for your needs

Free Samples

Quality testing before bulk orders

Factory Direct

Competitive pricing with quality assurance

Contact Our Team

Jackson Sin

International Sales Manager

+86 18575887164

Ledan Ye

Technical Support

+86 13868736731

Get Your Custom Quote

Tell us about your project and we'll provide a tailored solution