Custom DC Circuit Breaker Supplier

Professional DC circuit breaker customization with minimum order quantities from 100 units. Fast 7-15 day delivery, comprehensive OEM/ODM support, and 20 years of manufacturing excellence.

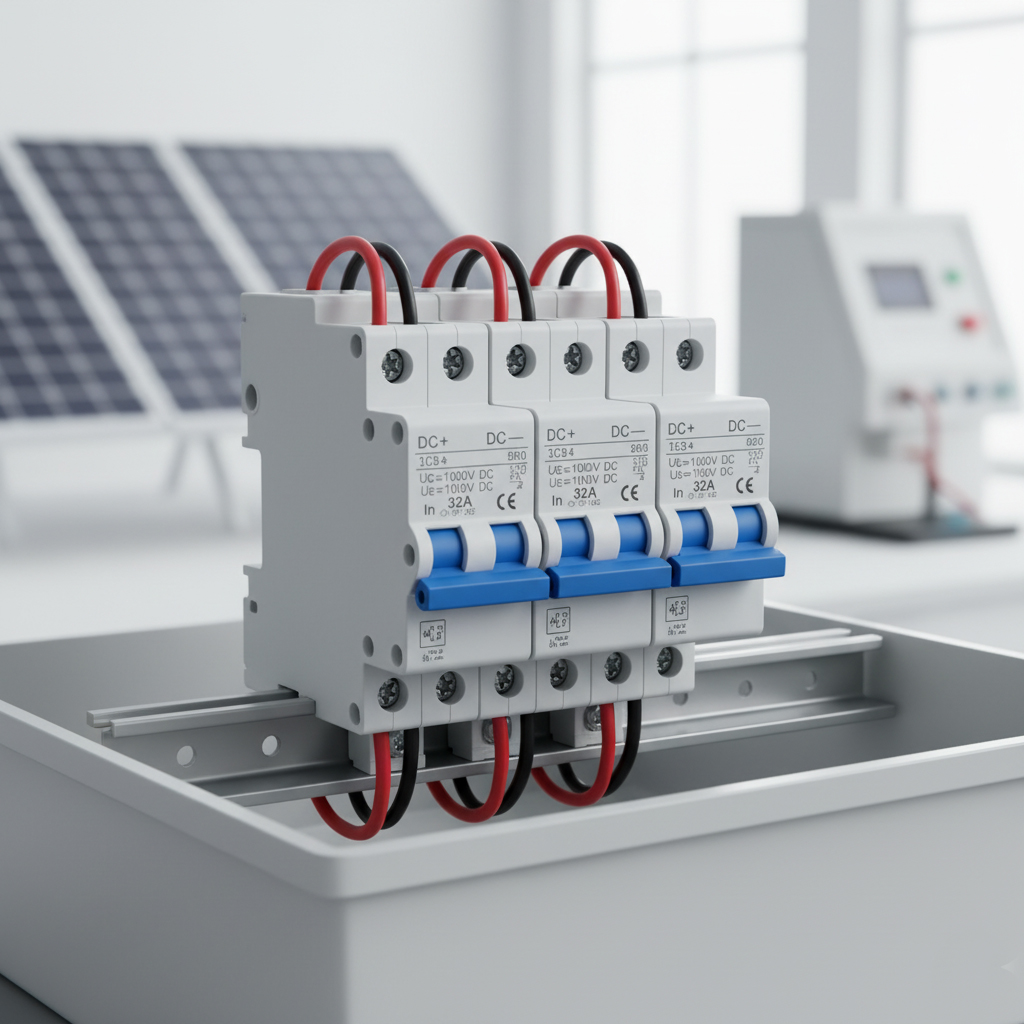

DC Circuit Breaker Series

Professional grade protection for solar PV systems

Your Premier DC Circuit Breaker Supplier

With 20 years of manufacturing expertise, XiangOu Solar has established itself as a premier supplier of DC electrical protection devices. Our ISO9001:2015 certified facility serves customers across North America, Europe, and Asia-Pacific markets.

20+

Years Experience

50+

Countries Served

24/7

Technical Support

5 Year

Quality Warranty

DC Circuit Breaker Excellence

Engineered for the future of solar energy with uncompromising quality and performance

DC MCB Series

Precision-engineered miniature DC circuit breakers for residential and commercial solar installations. Advanced arc interruption technology ensures reliable protection with superior breaking capacity up to 10kA.

DC MCCB Series

Industrial-grade molded case DC circuit breakers designed for utility-scale solar projects. Revolutionary arc extinguishing technology with intelligent thermal and magnetic protection systems.

Ready to Elevate Your Solar Project?

Connect with our engineering experts for customized DC protection solutions tailored to your specific requirements

Why Partner with XiangOu

Experience the advantage of working with a dedicated DC electrical protection specialist

Supply Chain Excellence

Reliable 7-15 day delivery with emergency rush order support. Strategic inventory management and flexible production scheduling ensure your projects stay on track.

Cost-Effective Customization

Competitive pricing with low MOQ from 100 units. Volume discounts and value engineering services to optimize your total cost of ownership.

Quality Management

ISO9001:2015 certified quality system with incoming, in-process, and final inspection protocols. 100% electrical testing and comprehensive quality documentation.

Technical Support

Direct access to our engineering team for application support, product selection, and custom design consultation. Comprehensive technical documentation and training resources.

Compliance & Certification

Full compliance with UL, IEC, and CE standards. Assistance with regional certification requirements and comprehensive test reports for your documentation needs.

After-Sales Warranty

Industry-leading 5-year warranty with responsive field support. Replacement parts availability and technical troubleshooting assistance throughout the product lifecycle.

Join hundreds of satisfied customers worldwide who trust XiangOu Solar for their DC electrical protection needs.

Frequently Asked Questions

Get expert answers to common questions about our premium DC circuit breaker products and professional services

What are your delivery times and rush order capabilities?

Standard delivery time is 7-15 business days for stock items and 15-25 days for custom configurations. We offer expedited service for urgent orders with 3-7 day delivery available for an additional fee. Our flexible production scheduling can accommodate critical project timelines.

What are your minimum order quantities and pricing structure?

Our minimum order quantity starts at 100 units for standard products and 500 units for custom configurations. Volume pricing tiers offer significant savings: 100-499 units (standard pricing), 500-999 units (5% discount), 1000-4999 units (10% discount), 5000+ units (15% discount plus additional negotiable terms).

Do you support custom specifications, materials, and packaging?

Yes, we offer comprehensive customization including custom current ratings, voltage levels, pole configurations, enclosure materials, mounting options, and terminal types. Custom packaging with your branding, specialized protective packaging, and private labeling services are available. Our engineering team works closely with you to develop optimal solutions.

What are your quality standards and warranty policy?

All products are manufactured under ISO9001:2015 quality management system with 100% electrical testing. We provide comprehensive test certificates and quality documentation. Standard warranty is 5 years with optional extended warranty programs. Defective products are replaced or repaired at no charge during the warranty period.

What is your sample policy and prototyping timeline?

Free samples available for standard products (customer pays shipping). Custom samples available for $50-200 depending on complexity, fully refundable with production order. Sample lead time is 3-7 days for stock items and 7-14 days for custom prototypes. We can provide up to 5 samples per customer for evaluation purposes.

What shipping methods do you offer and do you assist with customs clearance?

We offer multiple shipping options: Express (DHL, FedEx, UPS) for samples and small orders, Air freight for medium orders, and Sea freight for large volume shipments. We provide complete customs documentation, duty calculation assistance, and can arrange DDP (Delivered Duty Paid) terms for simplified import processes.

Still have questions?

Our technical experts are ready to help with your specific requirements

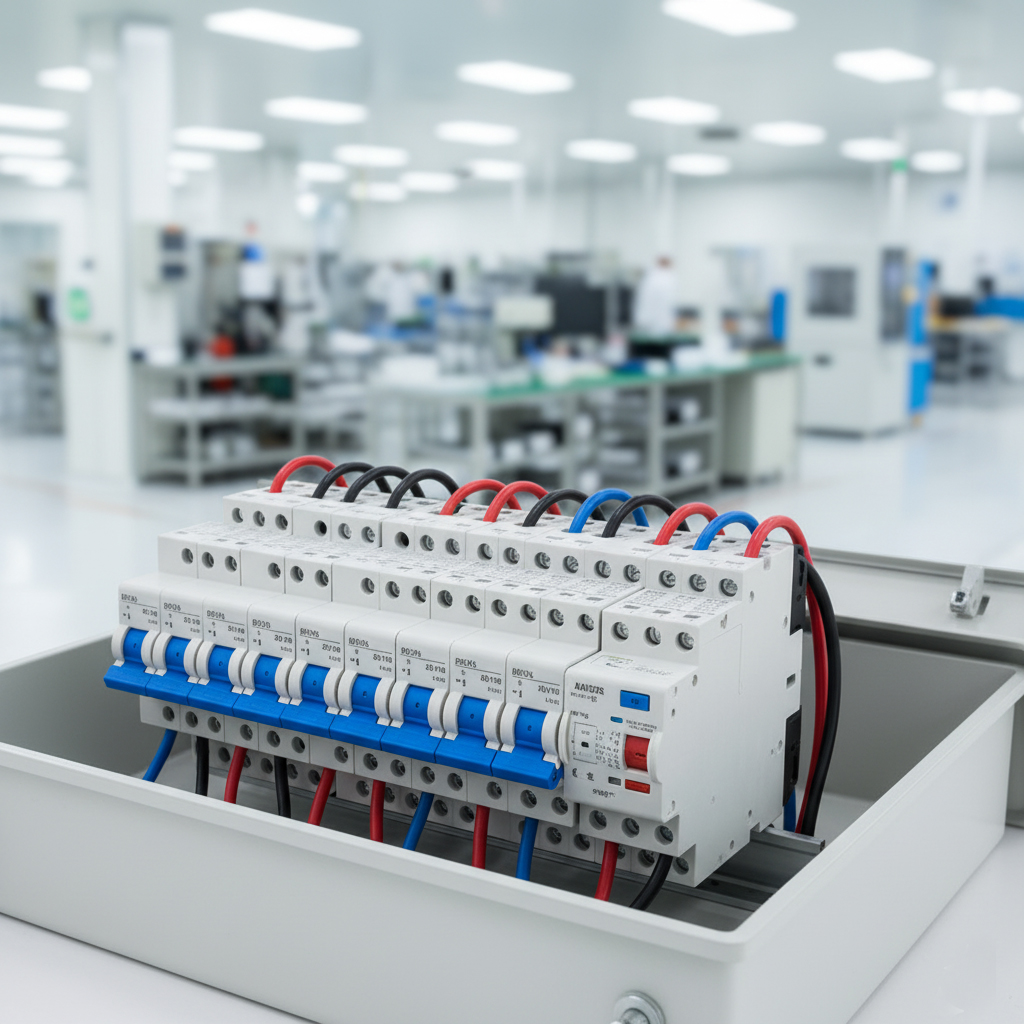

Production & Quality Control

Advanced manufacturing capabilities with rigorous quality assurance at every step of our precision engineering process

Production Capabilities

Automated Production Lines

4 fully automated production lines with monthly capacity of 500,000 units. Advanced robotics ensure consistent quality and precision manufacturing with zero-defect standards.

Advanced Equipment

State-of-the-art injection molding, precision machining, and automated assembly equipment from leading European manufacturers ensuring exceptional precision.

5000㎡ Modern Facility

Climate-controlled manufacturing environment with cleanroom standards for sensitive electronic components and contamination-free assembly processes.

Quality Assurance

Incoming Material Inspection

100% inspection of critical components including contact materials, arc chambers, and insulating materials using advanced spectroscopy and dimensional analysis.

In-Process Quality Control

Statistical process control with real-time monitoring of critical parameters. AI-powered automated rejection of non-conforming products with 99.9% accuracy.

Final Testing & Certification

Comprehensive electrical testing including trip characteristics, breaking capacity, and insulation resistance with full digital traceability and blockchain verification.

Custom Packaging

Anti-static bags, foam inserts, custom cartons with premium branding options and sustainable materials

ISO 9001:2015

Certified quality management system ensuring consistent excellence and continuous improvement processes

UL Listed

UL 489 certification for North American market compliance with rigorous safety standards

CE Marking

European conformity marking for IEC 60947-2 compliance ensuring global market acceptance

The Ultimate DC Circuit Breaker Guide

Comprehensive resource for engineers, procurement professionals, and project managers working with DC electrical protection systems. This guide addresses common challenges in product selection, quality evaluation, customization processes, and supply chain management to help you make informed decisions and achieve project success.

Guide Contents

Essential concepts and technical definitions

Comprehensive selection methodology

Industry standards and testing protocols

Custom solution development workflow

Comprehensive cost breakdown analysis

Logistics and risk mitigation strategies

Regulatory standards and certifications

Long-term support and maintenance

Key Questions Answered

How do I quickly determine if a DC circuit breaker suits my application?

Evaluate three critical factors: operating voltage and current requirements, breaking capacity needs based on fault current calculations, and environmental conditions including temperature, humidity, and installation location.

What are the 3 most important parameters when selecting DC circuit breakers?

Rated current (In), rated voltage (Un), and breaking capacity (Icn). These parameters must match or exceed your system requirements to ensure safe and reliable operation.

How do materials and manufacturing processes affect performance and cost?

Silver alloy contacts provide superior performance but increase cost by 15-20%. Thermoplastic housings offer good insulation at lower cost, while thermoset materials provide better high-temperature performance.

Custom Design Process

Step-by-step guide to developing effective custom solutions from initial requirements to production-ready prototypes.

Quality Control Framework

Comprehensive quality assurance protocols covering incoming inspection, process control, and final testing procedures.

Supplier Partnership Best Practices

Strategies for building long-term relationships with suppliers including communication protocols, performance metrics, and continuous improvement.

Start Your DC Circuit Breaker Project Today

Experience fast response times, dedicated engineering support, complimentary samples, and competitive pricing. Our team is ready to transform your specifications into high-quality DC protection solutions.

Get Your Custom Quote

Professional consultation within 24 hours